Our Al Friedrich helped co-author the article Effect of de-aeration on process ability of poorly flowing powders by roller compaction, we are pleased to let you know that the final version – containing full bibliographic details – is now available online for free for the next 50 days until June 30, 2022.

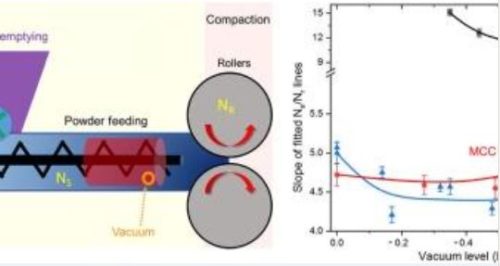

Dry granulation using a roller compactor is an important granulation technique for manufacturing pharmaceutical products as well as other materials. This study carried out at our academic research partner University of MN led by Prof. Sun focused on roller compaction (RC) of extremely cohesive powders. They can present a problem in roller compaction because they cannot be consistently fed into the slip and nip region of the rollers.

The use of a vacuum de-aeration mechanism, which is a standard offering on the Alexanderwerk roller compactors, can facilitate feeding of such difficult powders. This research was carried out using colloidal silica.

Cohesive pharmaceutical materials (low bulk density and cohesive powders) prepared by spray-drying, micronization, and freeze-drying are expected to benefit from the vacuum-aided powder feeding in RC.

Do you have such a challenging material and would like giving RC with vacuum de-aeration a try? We can offer our lab services and rental machines to you. Let’s talk! Please feel free to contact one of our local and global dry granulation experts where we can help you choose the best suitable granulation right from the beginning of your formulation process.

https://alexanderwerkinc.com/contact-us/

Here is the link to the article: https://authors.elsevier.com/c/1f33q1M49kXFHz