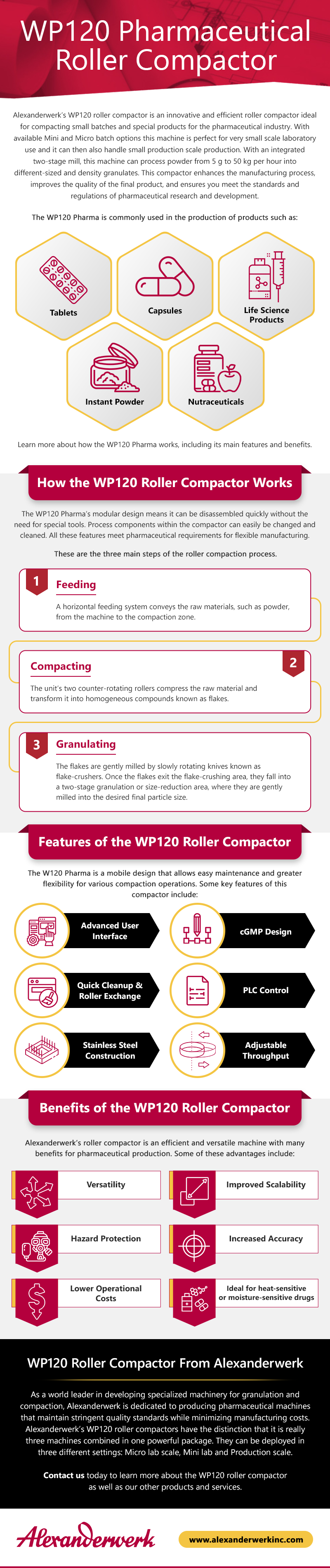

Alexanderwerk’s WP120 roller compactor is an innovative and efficient roller compactor ideal for compacting small batches and special products for the pharmaceutical industry. With available Mini and Micro batch options this machine is perfect for very small scale laboratory use and it can then also handle small production scale production. With an integrated two-stage mill, this machine can process powder from 5 g to 50 kg per hour into different-sized and density granulates. This compactor enhances the manufacturing process, improves the quality of the final product, and ensures you meet the standards and regulations of pharmaceutical research and development.

The WP120 Pharma is commonly used in the production of products such as:

- Tablets

- Capsules

- Life science products

- Instant powder

- Nutraceuticals

Learn more about how the WP120 Pharma works, including its main features and benefits.

How the WP120 Roller Compactor Works

The WP120 Pharma’s modular design means it can be disassembled quickly without the need for special tools. Process components within the compactor can easily be changed and cleaned. All these features meet pharmaceutical requirements for flexible manufacturing.

These are the three main steps of the roller compaction process.

Feeding

A horizontal feeding system conveys the raw materials, such as powder, from the machine to the compaction zone.

Compacting

The unit’s two counter-rotating rollers compress the raw material and transform it into homogeneous compounds known as flakes.

Granulating

The flakes are gently milled by slowly rotating knives known as flake-crushers. Once the flakes exit the flake-crushing area, they fall into a two-stage granulation or size-reduction area, where they are gently milled into the desired final particle size.

Features of the WP120 Roller Compactor

The W120 Pharma is a mobile design that allows easy maintenance and greater flexibility for various compaction operations. Some key features of this compactor include:

- Advanced user interface: The WP120 has an advanced user interface to control all compaction processes. The interface allows the operator to make precise throughput, compacting pressure, particle size, and flake density adjustments.

- cGMP design: The WP120 is designed in accordance with cGMP requirements, which ensures that all materials are properly compressed and meet the standards and requirements of the pharmaceutical industry. The production area is separated from the drives.

- Quick cleanup and roller exchange: The machine has a unique design that allows for fast and easy cleanup. It’s also equipped with a roller exchange system that enables seamless replacement of rollers as needed, ensuring optimal compaction. Compaction units come with different cantilevered roller combinations depending on the application.

- PLC control: With a programmable logic controller (PLC), operators can control the size and state of the output, ensuring efficient compaction and accurate operation. Available CFR21 conformity as well as recipe and batch controls make the Alexanderwerk WP120 especially well suited for the pharma industry.

- Stainless steel construction: The WP120 is made of stainless steel, making it durable and long-lasting.

- Adjustable throughput: The WP120 can process powder from 5 g to 50 kg/h. It also comes with a feedback control loop that optimizes repeatability and product consistency.

Benefits of the WP120 Roller Compactor

Alexanderwerk’s roller compactor is an efficient and versatile machine with many benefits for pharmaceutical production. Some of these advantages include:

- Versatility: The WP120 is one of the most versatile roller compactors on the market. The WP120 can be utilized as a lab scale compaction trial machine using the Micro Batch set up for even the smallest material amounts. With the Mini Batch 25mm roll set up small lab or production runs can be achieved. With the standard 40mm wide rolls the WP120 can be utilized in smaller production scale operations. The WP120 is also set up to be integrated and operated in continuous manufacturing mode.

- Improved scalability: The WP120 can be scaled up or down to meet the operator’s needs, producing laboratory trial, commercial, or pilot production quantities on demand.

- Hazard protection: Basic designs offer OEB (Occupational Exposure Band) designs that have an intrinsic level of protection against exposure often minimizing the need for PPE.

- Increased accuracy: The roller compactor’s accuracy and repeatability ensure consistent product quality. You can consistently produce granules of the same size and weight.

- Lower operational costs: The WP120 roller compactor reduces the time it takes to make products by eliminating stages like material wetting and drying. This saves resources, time, and labor costs especially in comparison to wet granulation techniques.

- Ideal for heat-sensitive or moisture-sensitive drugs: Since the WP120 roller compactor doesn’t involve the addition of liquids to the material during compaction and granulation typically deployed in wet granulation, it’s an excellent choice for manufacturing pharmaceutical products that are sensitive or ineffective when exposed to moisture. These products also don’t need to be dried using heat, so the WP120 preserves the efficacy of heat-sensitive active ingredients.

WP120 Roller Compactor From Alexanderwerk

As a world leader in developing specialized machinery for granulation and compaction, Alexanderwerk is dedicated to producing pharmaceutical machines that maintain stringent quality standards while minimizing manufacturing costs. Alexanderwerk’s WP120 roller compactors have the distinction that it is really three machines combined in one powerful package. They can be deployed in three different settings: Micro lab scale, Mini lab and production scale, and Production scale.

Contact us today to learn more about the WP120 roller compactor as well as our other products and services.