Alexanderwerk Experts support Top Hands-On Training Event in the US (April 20 – 22, 2021)

Comentarios desactivados en Alexanderwerk Experts support Top Hands-On Training Event in the US (April 20 – 22, 2021)

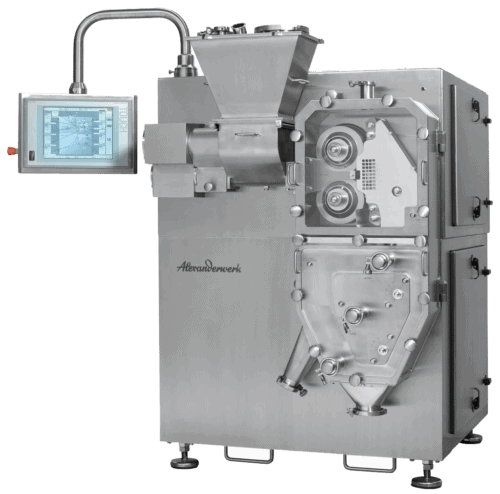

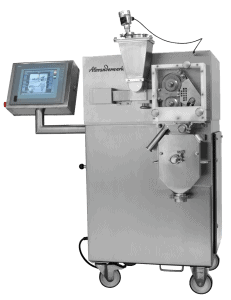

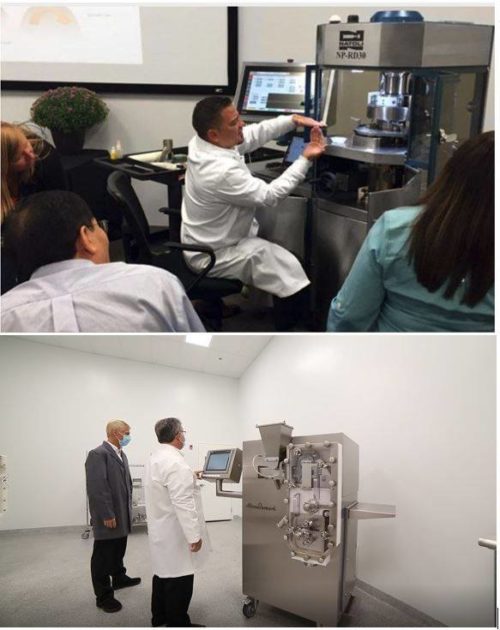

Our partner Natoli Scientific organizes a 3-day-seminar in Telford (PA) and our experts from Alexanderwerk Inc. will support this top hands-on training event. The seminar will take place at the Natoli Scientific Center in Telford (April 20 – 22, 2021). Hurry up to get registered for this event as seats are limited.

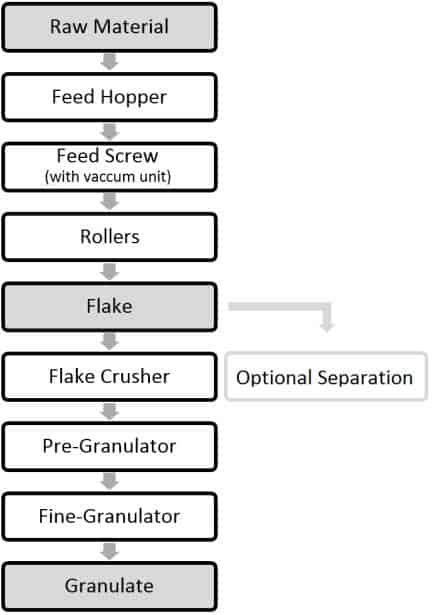

Natoli is well-known for their tablet presses, tooling, and also for their global reach in training formulators and operators. The partnership with Natoli began years ago and we are happy, that our colleague Al Friedrich, National Sales Engineer Alexanderwerk Inc., will support Robert Sedlock and his team at Natoli in Telford (PA, USA). Mr. Friedrich will do the lectures on Dry Granulation and Milling.

And don’t miss the chance to visit our lab in Montgomeryville, which just a 20 minute drive from Telford!

The organizer’s website can be reached here. Please contact Natoli’s team for further Covid-19 and implemented hygienic concepts and requirements.

A flyer for the seminar can be downloaded from Natoli’s website.