Continuous Dry Granulation by Compactación por Rodillos -

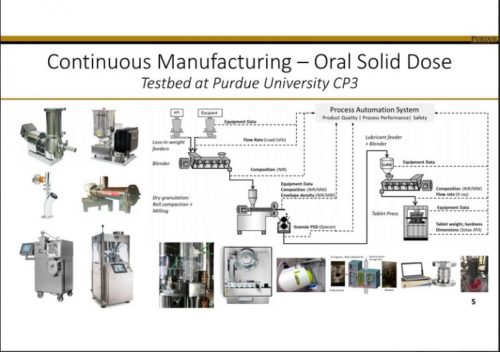

Continuous dry granulation by roller compaction is a well-established process in pharmaceutical, chemical and life science industry. In pharmaceutical applications the most common target is to increase the flowability of a powder or powder blend to enable the fast and homogeneous feeding of a tablet press.

The challenge is to produce tablets of constant weight and sufficient strength, while maintaining an even distribution of the Active Pharmaceutical Ingredients (API). This can be achieved by roller compaction for a wide range of products and without the need of additional ingredients such as binders, moisture or lubricants.

Furthermore, dry granulation by roller compaction is used to eliminate dust, increase the bulk density, reduce the storage volume, improve handling and manipulate the dissolution properties. Please feel free to download the following whitepaper to get more insights: ShinEtsu – Protocol: Continuous Dry Granulation by Roller Compaction

The secret behind the “HIGHEST QUALITY GRANULES”

We are often asked – Why does Alexanderwerk create the highest quality granules? Here are (some of) the answers…

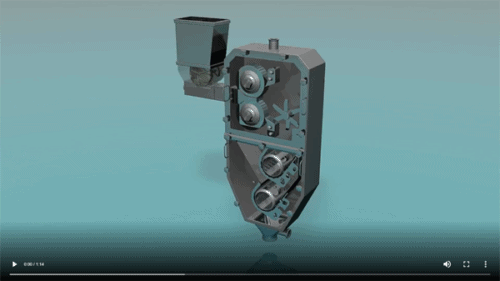

Alexanderwerk roller compactors produce the highest quality of granules compared to all other roller compactors. This is mainly because Alexanderwerk has optimized the entire compaction and granulation process. The quality of the process starts already with the correct intake of raw material in the hopper.

An optimized design ensures a good supply of material and prevents caking and clogging. The integrated stirrer prevents clumping in the feed area of the auger and ensures good material handling. The patented Combi-Vent feeder increases throughput and also contributes to a uniform mixing of raw and return material.

The vertical arrangement of the rollers, in combination with the unique nip control, ensures uniform density and bucket volume. The unique control concept makes it possible to operate the nip with an accuracy of +/- 0.1 mm. As a result, the slugs have a uniform thickness.

Also, the material supply is controlled continuously, so that at constant roller pressure, there can be no fluctuations in the density. Last but not least, the 3-stage shredding process guarantees the gentlest shredding compared to all other competitors. Basically, Alexanderwerk roller presses generate a much lower proportion of fines than all other roller compactors.

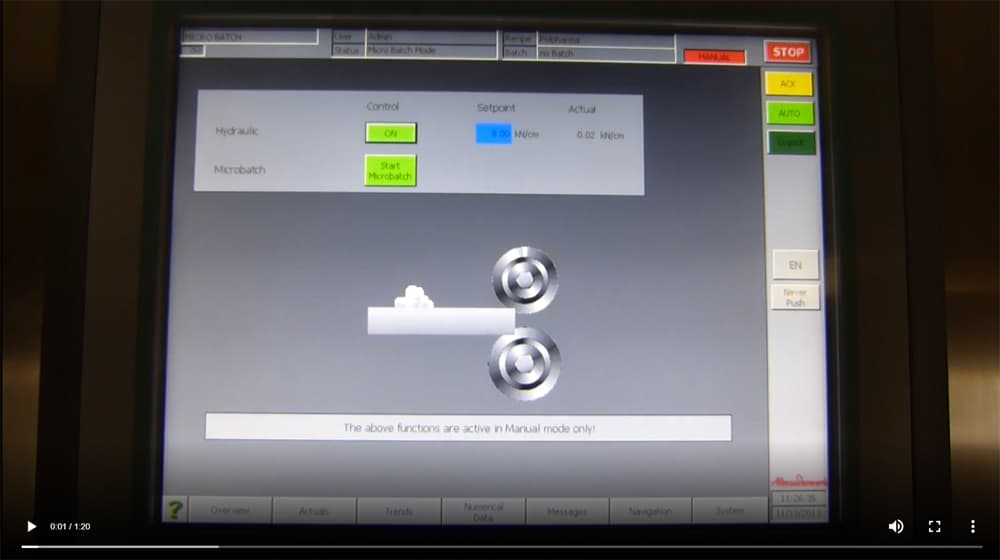

Minimal amounts with a “Micro Batch”

Alexanderwerk can process the smallest amounts of powders that can be produced on a Roller Compactor. As little as 1 gram of a material is sufficient to be processed on a WP 120 Pharma euqipped witht the Micro Batch module. Designed for early-stage testing or high value products, the Micro Batch module offers you high flexibility and huge cost savings.